-

The Monforts range combinations for denim finishing are now even more cost-efficient and eco-friendly.

The Monforts range combinations for denim finishing are now even more cost-efficient and eco-friendly. -

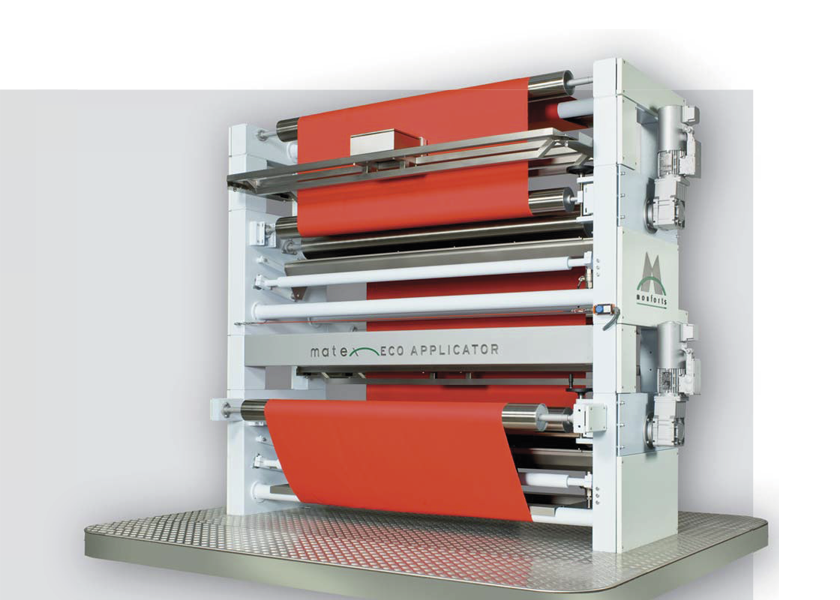

Following the high acceptance and high profitability of the original Monforts ECO Applicator the spectrum of applications has now been extended to the field of knitted fabric treatment.

Following the high acceptance and high profitability of the original Monforts ECO Applicator the spectrum of applications has now been extended to the field of knitted fabric treatment. -

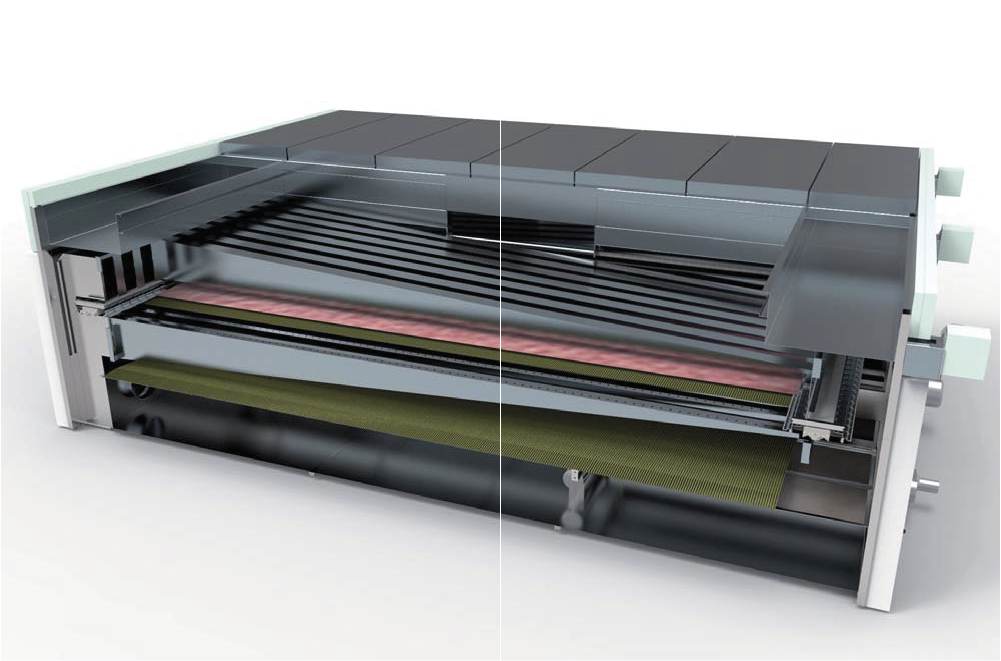

In line with the demands of our times, the proven MONTEX stenter design is now also available with large working widths.

In line with the demands of our times, the proven MONTEX stenter design is now also available with large working widths. -

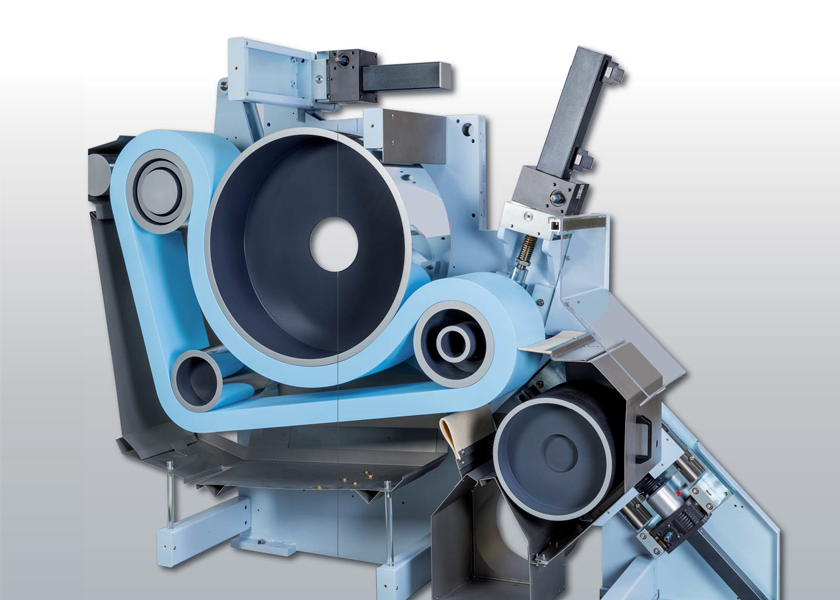

Monfortex / Toptex compressive shrinkage ranges are among the best of their kind.

Monfortex / Toptex compressive shrinkage ranges are among the best of their kind. -

Interchangeable module for stenter and coating operation mode. Quick adaptation according to finishing demands. Available: modules for different knife systems as knife over roll and knife over air, foam coating and Commabar. Under preparation: modules for slot coating(cold systems) and printing processes like rotary screen printing, gravure and flexo printing as well as modules for dipping and impregnation processes and powder scattering. Special modules like for example lamination module and skewing module Flexible adaptation according to desired finishing method Different coating solutions Multiple machine application for classical textiles and for technical textiles Solvent application possible* Distance between coating substrate application and pinning in position as close as possible Easy cleaning of the device thanks to slide-in/slide out technology with trolley * special execution required Kaplama Kafası Modülü Rotasyon Baskı Modülü Giriş ve İlave Besleme Modülü

Interchangeable module for stenter and coating operation mode. Quick adaptation according to finishing demands. Available: modules for different knife systems as knife over roll and knife over air, foam coating and Commabar. Under preparation: modules for slot coating(cold systems) and printing processes like rotary screen printing, gravure and flexo printing as well as modules for dipping and impregnation processes and powder scattering. Special modules like for example lamination module and skewing module Flexible adaptation according to desired finishing method Different coating solutions Multiple machine application for classical textiles and for technical textiles Solvent application possible* Distance between coating substrate application and pinning in position as close as possible Easy cleaning of the device thanks to slide-in/slide out technology with trolley * special execution required Kaplama Kafası Modülü Rotasyon Baskı Modülü Giriş ve İlave Besleme Modülü -

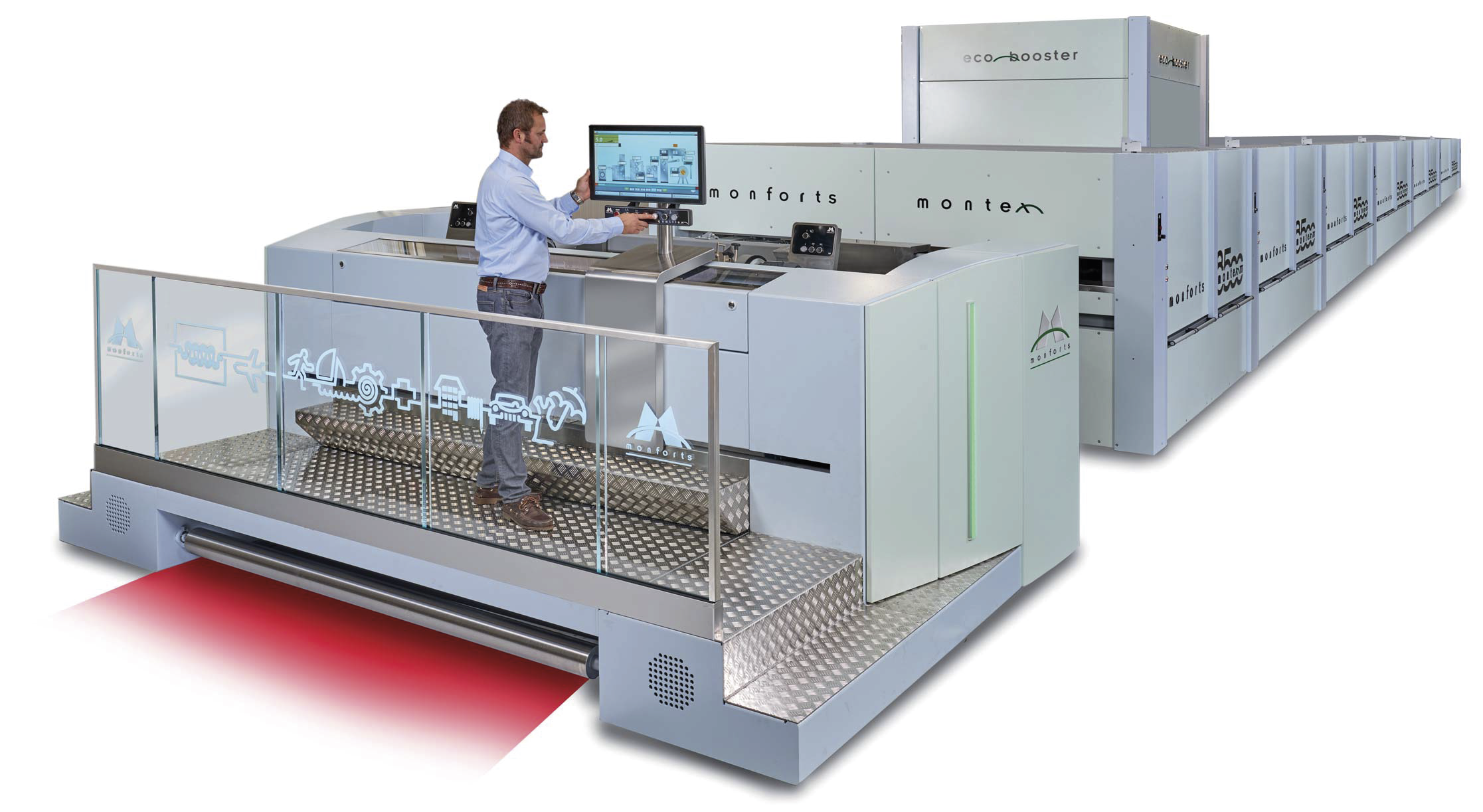

The concept of the original Montex stenter acknowledged and proven worldwide has been adapted to the demands of our time and to the latest needs of textile finishing: more modern, more versatile, more flexible, more eco-friendly.

The concept of the original Montex stenter acknowledged and proven worldwide has been adapted to the demands of our time and to the latest needs of textile finishing: more modern, more versatile, more flexible, more eco-friendly. -

Sustainable technology for the dyeing of PES/cellulose and elastane-based blends

Sustainable technology for the dyeing of PES/cellulose and elastane-based blends -

The revised and further optimised Qualitex 800 visualisation software offers the operator even more reliability and benefits.

The revised and further optimised Qualitex 800 visualisation software offers the operator even more reliability and benefits.